The vacuum conveyor transports materials through negative pressure, utilizing a closed pipeline system that prevents dust leakage. It can transport particles ranging in size from 0.2 microns to 1 millimeter. Our Ti07 filter, made from imported filter material, has a filtration efficiency of 99.99%, ensuring no dust passes through the filter into the environment. The system operates with noise levels below 70 decibels.

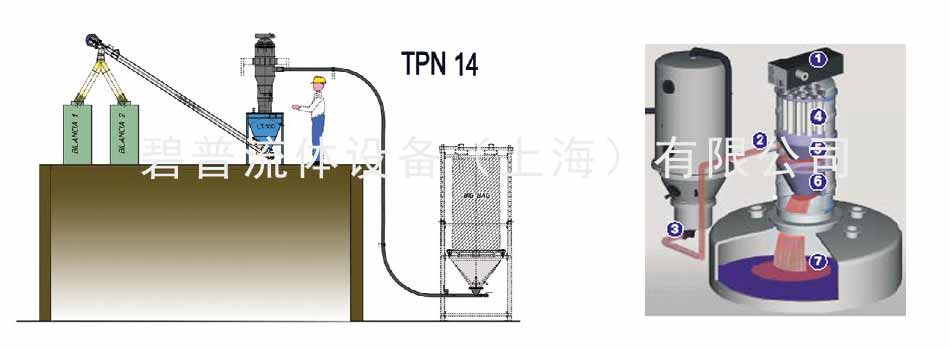

Operating Principle:

Under vacuum conditions, the vacuum conveyor generates a negative pressure airflow. This airflow instantly transports bulk materials through suction hoses or pipes to another container. Since the materials remain in a vacuum state during transfer, even if a pipeline leak occurs, the materials will not leak into the surrounding environment.

Operation Sequence:

A. The roots blower generates a vacuum in the separator container of the vacuum conveying equipment, drawing materials from the feed inlet through the suction hose and into the suction entry.

B. Air and material are separated in the filter chamber of the separator container, collecting materials in the storage bin. A cyclone separator prevents fine powder from entering the filter, enhancing filter efficiency.

C. Once the storage bin is full, the converter automatically shuts off, and the pressure within the conveying equipment reaches equilibrium. The discharge valve opens, allowing material to flow out through the discharge outlet and directly into the storage container.

E. The discharge chamber closes, and the entire conveying process restarts.

Equipment Components:

The system primarily consists of a roots blower, filter chamber and filter, backflushing air, separator chamber, storage bin, pneumatic discharge valve, pneumatic vibrator, quick-release clamp, seal (natural silicone rubber), pneumatic controller, and connection system.

Product Features:

- Simple: PLC automatic control.

- Hygienic: Meets GMP standards and CIP requirements.

- Clean: Dust-free operation, preventing environmental pollution during the conveying process.

- Economical: Low maintenance costs.

- Safe: No heat generation during operation and explosion-proof.

|

项目/型号 |

BIOP180型 |

BIOP250型 |

BIOP320型 |

BIOP430型 |

BIOP560型 |

BIOP800型 |

|

压缩空气 /压力 |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

|

压力/ 耗气量 |

0.4M3/min |

0.7M3/min |

1.3M3/min |

2.7M3/min |

3.6M3/min |

4.5M3/min |

|

输送能力 |

0.1-0.5T/h |

0.3-0.8T/h |

0.5-1.2T/h |

1.3-3.5T/h |

2.5-6.0T/h |

5.0-10.0T/h |

|

过滤器 |

Ti07德国进口滤芯,PTFE滤芯,Ti烧结式滤芯 |

|||||

|

过滤面积 |

0.33M2 |

0.33M2 |

0.99M2 |

2M2 |

2.3M2 |

3.3M2 |

|

吸料口经 |

DN38 |

DN50 |

DN75 |

DN100 |

DN100 |

DN150 |

|

下料口径 |

φ150 |

φ150 |

φ200 |

φ200 |

φ250 |

φ300 |

|

真空料仓容积 |

7L |

18L |

35L |

56L |

96L |

250L |