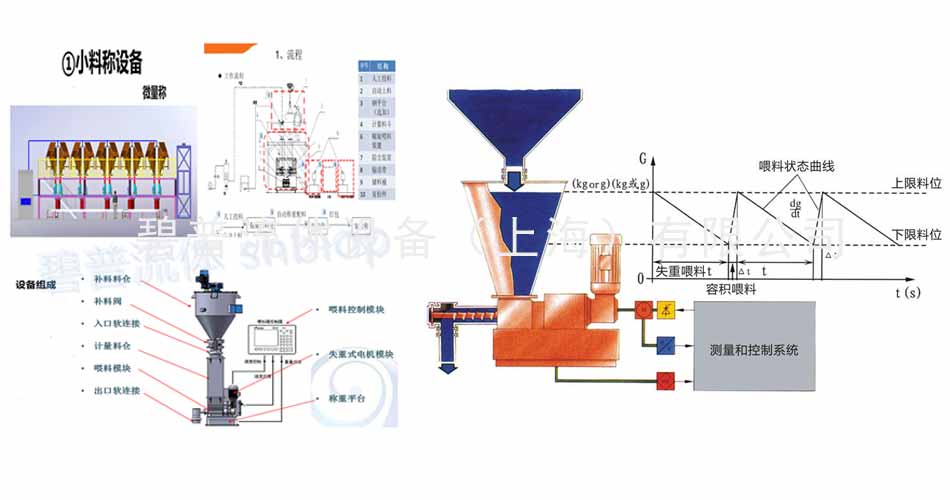

Working Principle:

The outfeed screw or electric vibratory feeder is controlled based on the rate of decrease in the weight of the material in the weighing hopper, achieving the goal of accurate feeding. When the material in the weighing hopper reaches the lower weight limit, the outfeed screw functions at a fixed discharge rate according to its current rotation speed, simultaneous to controlling the quick descent of material from the storage bin into the weighing hopper. When the material fills to the upper weight limit, the filling stops, and rapid filling minimizes the feeding time, thereby improving the accuracy of weighing and control precision.

1. Features:

1. Raw material batch management and fully automated batching.

2. Various metering combinations offered based on customer requirements to satisfy their needs.

3. Uses variable frequency multi-stage feeding to effectively improve batching accuracy.

4. Modular combinations can be configured based on the number of storage bins.

5. Professional dust recovery system effectively prevents residuals.

6. Displays alarm information and common fault causes along with troubleshooting methods for easy resolution; capable of connecting to a printer for data printing.

7. Data storage capability.

2. Structure:

1. Function Realization and Principle: Based on set recipe ratio requirements, it utilizes a digital closed-loop control principle with high-precision, high-dynamic response C6-grade sensors to continuously detect the flow of bulk materials (granular or powdered). The industrial computer system compares the detected flow with the set flow value and compensates for deviations by adjusting the feeder motor speed through intelligent software.

2. Feeding Modes and Operating States: Weight-based (GF), volume-based (VF), discharge-based (DI), weight-based discharge (GD), and maximum feeding mode (CM).

3. Combined Working Modes: Percentage and single machine modes; normal operation uses the percentage mode.

4. Measurement Alarm Functions: High and low speed, excessive deviation (more or less feeding), overload, underload, refilling errors, communication alarms, drive alarms, unsatisfied start conditions, with options for linked alarms to stop or not stop the machine.

5. Starting Conditions (Parameters to Set Before Operation): Bulk density, CM value, overload > refill upper limit > refill lower limit > underload, material weight < refill lower limit, tare weight, set value > maximum feeding value.

6. Other Functions: Maximum refill time setting, tare weight, static and dynamic calibration of weighing sensors, PID parameter settings, recipe storage, operational and alarm information inquiry, and standard electrical indications and alarms.

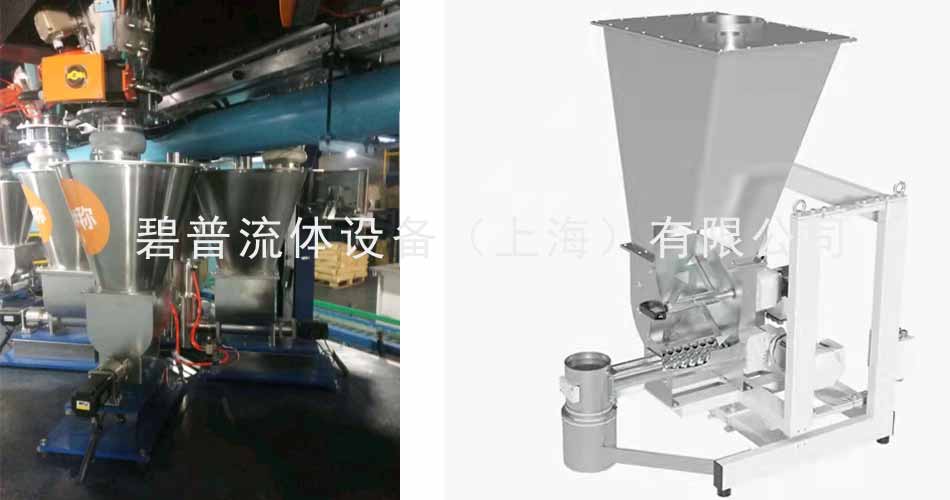

7. Mechanical Components: Weighing platform, gearbox (integrated motor and gearbox), distribution box (for distributing output to shafts and horizontal stirring), horizontal mixing paddles, vertical stirring (optional according to material, includes motor + gearbox + mixing paddles), screw tube, screw, discharge outlet blocking device (to prevent residual material drips), hopper and lid, seals, and other accessories.

8.Electrical Components: AC motor (or servo motor), inverter (or servo controller), speed sensor, PLC, weighing sensor, weighing instruments, and other standard electrical components.